Overview: Computational fluid dynamics (CFD)

With the advancement in technologies. The expectations of consumers and engineers from automobiles are skyrocketing. This man-made machine, which was invented to help us commute, is now on the verge of becoming a man-made marvel. With incessant technological development. Engineers are now building automobiles that would have been unfeasible 20 years back in time. All this is made attainable by Computer-Aided Engineering (CAE). Including the highly efficacious technique of Computational Fluid Dynamics or CFD.

A technical glimpse: CFD

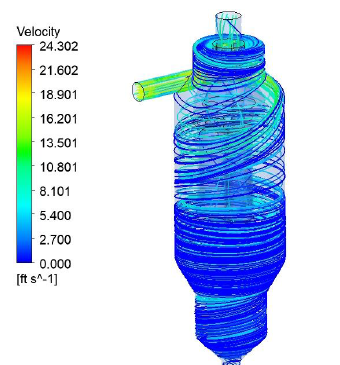

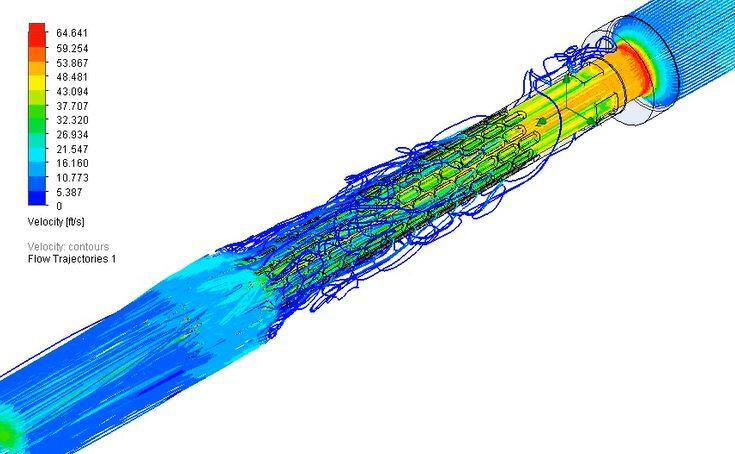

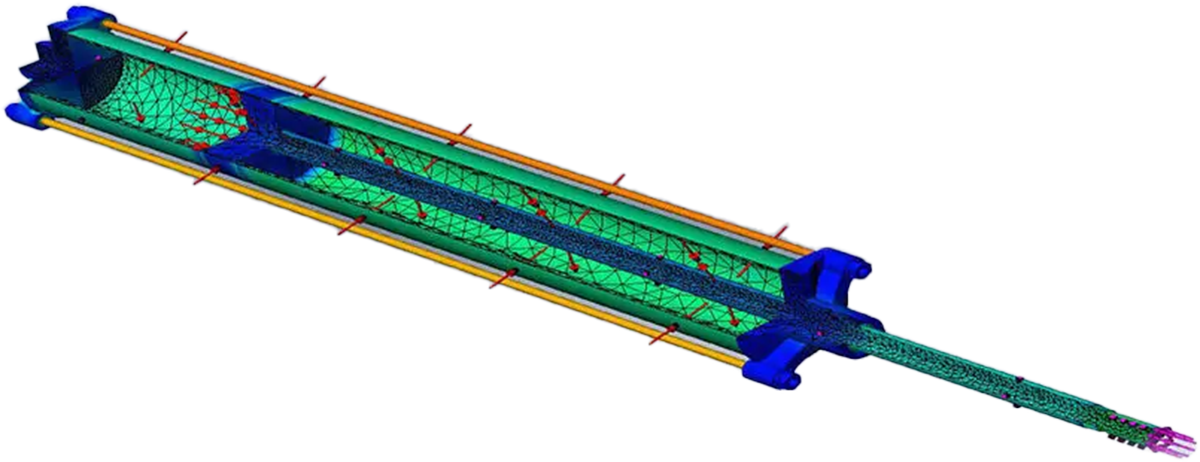

CFD is employed wherever there is an interaction of a component with gas, fluid, or even solid or any combination of these. Utilizing the CFD simulation method negates the need to perform complex hand calculations. CFD simulation executes calculations by cleaving the 3D component. Into innumerable tiny equal-sized elements. All these elements are related to one another by complex mathematical equations. Namely; The Navier-Stokes equations, represent any flow mathematically.

How Crucial is CFD simulation for Automobiles?

CFD plays a significant role in the advancement and development of modern automobiles. This computational technique allows engineers and experts to predict and investigate heat or fluid flow surrounding a component. CFD enhances the process of designing a component, assembly or even developing the whole vehicle.

The efficacy of CFD simulation has allowed engineers to –

- Curtail on the expenses while building an automobile

- Analyze the effect of the surrounding conditions on any part

- Optimize the design of any component or assembly

- Shape the body contours of performance vehicles to minimize drag and lift

- Ensure the heat released from the engine is regulated properly

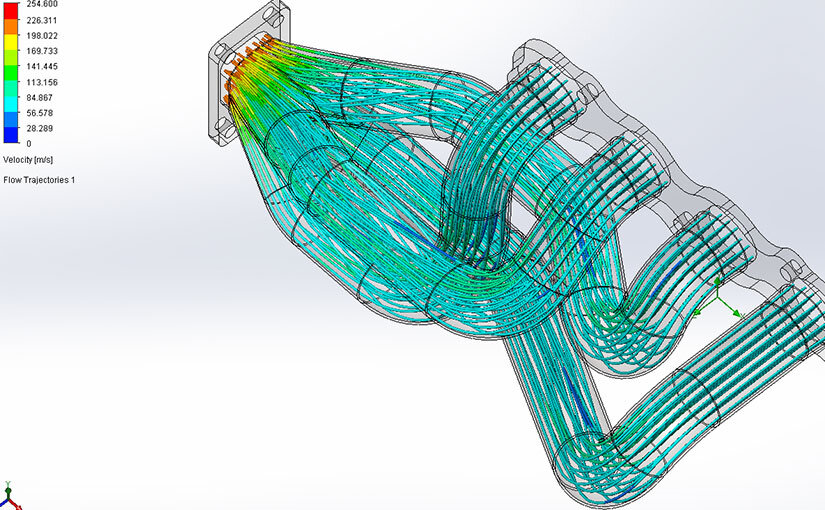

- Examine the fluid flow in various valves and intake manifold of the engine

CFD Applications in Automotive Sphere

There are innumerable other CFD applications that are essential while designing a vehicle. Let’s discuss those in detail-

Aerodynamics

The demand for better handling, a better performing, and a better-designed vehicle has been rising for a few years. Notably, high performing supercars and race cars have undergone drastic changes in their design. When compared to their earlier generations.

Moreover, these alterations in exterior design are to be incessantly felt in the next-generation cars as well. CFD applications in aerodynamics have supplemented engineers with the shrewdness to optimize the design of a vehicle. Analyzing the scaled-down CFD model of cars using CFD simulation has eliminated the need for wind-tunnel tests. With the ability to alter air quality, flow direction, density, speed. Experts can analyze the vehicle’s aerodynamic response to the surrounding factors, effectively using Computational Fluid Dynamics.

Why is CFD simulation Important for Automotive Aerodynamics?

- Helps improve the performance of the vehicle

- Aid engineers to optimize vehicle design for better aerodynamic response

- Increase the efficiency of the vehicle by minimizing aerodynamic losses

- Help designers work on the aesthetics of an automobile as per constraints.

Fuel-Air Mixture

Combustion of fuel to generate power has been our fundamental source of energy. Computational Fluid Dynamics offers a simple approach to determine the amount of heat released. When a certain mass of fuel burns inside the engine’s combustion chamber.

Moreover, CFD Simulation offers a solution to other problems on thermodynamics of combustion-

- Determine the exact position of reaction taking place inside the combustion chamber of the engine

- Temperature distribution inside the combustion chamber

- Amount of heat encountered by the piston, injectors, and the cylinder walls during combustion.

- Help compute the fuel-air ratio that produces the desired output from the engine.

- Helps to optimize the design of components used inside the cylinder. To aid in the preparation of a more uniform fuel-air mixture for proper combustion to cut waste fuel

Fuel Gases

Designing the components for the better departure of flue gases is as important as designing the intake manifolds. CFD simulation helps engineers to visualize the flow of flue gases out of the exhaust manifold.

Foreseeing the departure of flue gases from the exhaust using the CFD model help engineers to-

- Analyze the heat that is being released into the atmosphere

- Minimize the speed of exhaust gases exiting from the manifold

- Estimating the amount of unburned fuel

Thermal Heat Management

The efficiency of all the modern heat engines is determined by its ability to release heat into the atmosphere. Modern automobile engines producing an awe-inspiring amount of power. It becomes inevitable for engineers to design components. Capable of releasing the heat into the atmosphere.

Along with the other CFD applications. The Heat management application of the CFD simulation helps engineers to-

- Analyze the heat dissipation from various under-hood Engine components

- Estimate the heat conduction by the piston, cylinder, crankshaft, camshaft. And other components close to the engine cylinder

- Analyze the heat released by the engine block into the atmosphere. To Optimize the design by utilizing fins for better thermal heat management

To Conclude,

The CFD applications are enormous in the automotive sphere. Ranging from an automobile’s exteriors to its convoluted engine parts. When designing components or assemblies pertinent to the automotive industry. Almost everywhere CFD simulation is engaged. Everything relevant to a vehicle is encountered by some kind of flow, that can be analyzed using Computational Fluid Dynamics.

Notably, CFD consulting services offered by Imaginationeering can help optimize the existing designs. Experts offering CFD services can utilize the full potential of CFD simulation to contrive the desired output. With the expert’s guidance, employing CFD simulation could be profitable. Specifically, for solving problems associated with fluid flow.