In industries where efficiency and precision are paramount, advancements in Computational Fluid Dynamics (CFD) have revolutionized the design and optimization of equipment like cyclone separators. Cyclone CFD separators, integrating sophisticated CFD services, have emerged as critical tools for enhancing process efficiency across various sectors. This guide explores the key benefits and applications of cyclone CFD separators, shedding light on their transformative impact.

Understanding Cyclone CFD Separators

Cyclone separators are essential components in industries ranging from oil and gas to pharmaceuticals and mining. They function by using centrifugal force to separate particulate matter from gas streams, thereby improving air quality, reducing emissions, and enhancing overall process efficiency. Traditional cyclones were designed empirically, but with advancements in CFD technology, their design, optimization, and performance evaluation have become significantly more precise and effective.

The Role of CFD Services in Cyclone Separator Design

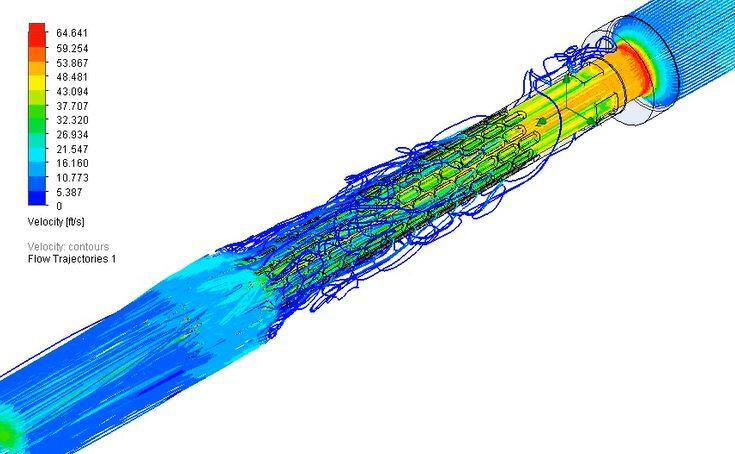

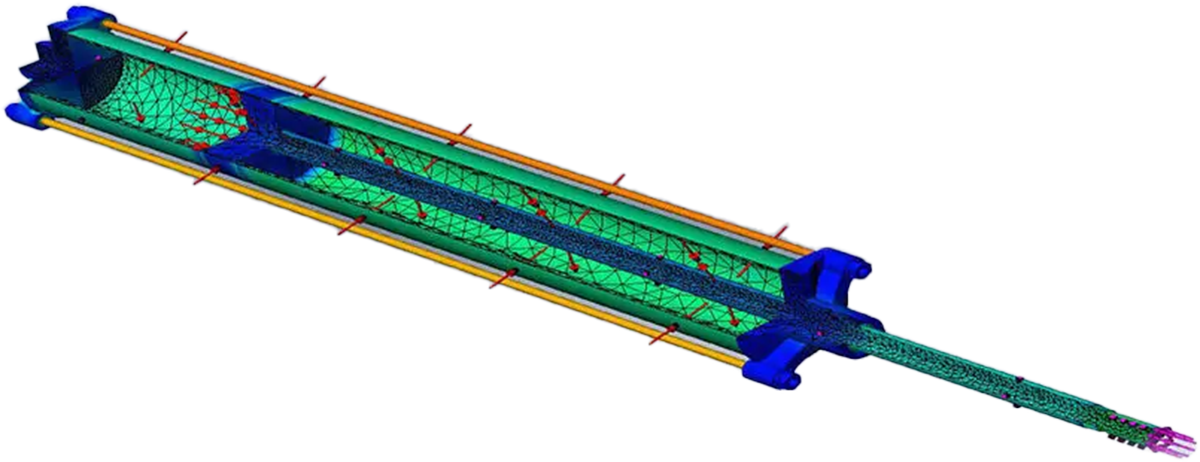

CFD consulting firms and CFD companies play a crucial role in the development and optimization of cyclone separators. By leveraging CFD simulations services, engineers can analyze complex flow patterns, turbulence, and particle trajectories within cyclones. This allows for the fine-tuning of design parameters such as inlet geometry, cyclone dimensions, and outlet configurations to maximize separation efficiency.

Key Benefits of Cyclone CFD Separators

1. Improved Efficiency and Performance: CFD simulations enable engineers to optimize cyclone designs for maximum particle separation efficiency. By accurately predicting flow behavior and optimizing internal geometries, cyclone CFD separators can achieve higher separation efficiencies compared to traditional designs.

2. Cost Reduction: Efficient cyclone designs lead to reduced energy consumption and maintenance costs. CFD simulations services help identify potential design flaws early in the development stage, minimizing the need for costly redesigns and ensuring optimal performance from the outset.

3. Enhanced Product Quality: In industries such as food processing and pharmaceuticals, maintaining product purity is crucial. Cyclone CFD separators ensure that particulate contaminants are effectively removed from gas streams, resulting in cleaner products and compliance with stringent quality standards.

4. Environmental Benefits: By improving separation efficiency, cyclone CFD separators contribute to reduced emissions and environmental impact. Cleaner exhaust gasses mean lower particulate emissions, aligning with sustainability goals and regulatory requirements.

5. Customization and Flexibility: CFD simulations allow for rapid prototyping and iterative design improvements. Engineers can explore various design alternatives and select the optimal configuration based on specific process requirements and constraints.

Applications Across Industries

The versatility of cyclone CFD separators extends across diverse industries:

– Oil and Gas: Used for gas-solid separation in refining and petrochemical processes.

– Mining: Efficient dust collection in ore processing and material handling operations.

– Pharmaceuticals: Ensuring clean air environments in production facilities to meet strict hygiene standards.

– Food Processing: Separation of food particles and contaminants from processing air.

Choosing the Right CFD Consulting Partner

When embarking on the design or optimization of cyclone CFD separators, selecting the right CFD consulting firm is crucial. Look for companies with a proven track record in computational fluid dynamics, experience across relevant industries, and a commitment to delivering actionable insights that drive tangible improvements in cyclone performance.

Conclusion

Cyclone CFD separators represent a significant advancement in industrial process optimization, offering enhanced efficiency, reduced environmental impact, and improved product quality. By harnessing the power of CFD simulations, engineers can design cyclone separators that not only meet but exceed performance expectations. As industries continue to prioritize efficiency and sustainability, cyclone CFD separators are poised to play an increasingly integral role in shaping the future of industrial processes.

Incorporating cyclone CFD separators into your operations can lead to substantial benefits, from cost savings to regulatory compliance and beyond. As technology evolves, so too will the capabilities of cyclone separators, driven by ongoing innovations in computational fluid dynamics and the expertise of CFD consulting firms worldwide.

For businesses seeking to optimize their processes and stay ahead in competitive markets, investing in cyclone CFD separators backed by expert CFD services is not just advantageous but essential for long-term success.