Finite Element Analysis (FEA) is one of the tools that has developed over the ages to extensively verify, validate and optimize the performance of ideas or products under structural loads and conditions. FEA is very useful especially for validating the strength and stability of the design under actual loading conditions. FEA helps in assessing the structural performance of the design under static, dynamic or cyclic loads. FEA not only checks for instantaneous failures, but also predicts the onset of failure under dynamic conditions and number of cycles to complete failure where the design will completely fail under repetitive or cyclic loading conditions.

One of the main industries where FEA is highly being used is in Construction Industry. Based on the type of requirements and analysis in Construction Industry, various FEA simulation services are required to perform simple as well as complex FEA analysis. Along with the FEA simulation services, FEA consulting engineers are not only required to perform the structural analysis, but also to understand the FEA analysis and recommend any design changes to the clients. FEA analysis services and FEA simulation services not only help in lowering the cost of the organizations, but also give a competitive edge and quality solution from a team of fea consultants who are specialized in this field and provide the required skill and experience for the job.

Finite element analysis (FEA) is an extremely useful tool in the field of civil engineering for numerically approximating physical structures that are too complex for regular analytical solutions. Consider a concrete beam with support at both ends, facing a concentrated load on its centre span. The deflection at the centre span can be determined mathematically in a relatively simple way, as the initial and boundary conditions are finite and in control. However, once you transport the same beam into a practical application, such as within a bridge, the forces at play become much more difficult to analyse with simple mathematics. Whether you are building a simple residential building or the next Burj Khalifa, understanding the structural behaviour and integrity of your building is extremely important to ensure the safety of its occupants.

Originally, civil engineers used laboratory experiments to solve these design problems, especially in regards to the behaviour of the steel structures when subjected to high wind loads and earthquakes. However, such reliance on laboratory testing was costly and not immediately accessible. Thus, FEA simulation services and FEA analysis services came into existence to develop FEA codes which can be used for Construction Industry. These codes made it easier for FEA consulting engineers to define what sort of behaviour was acceptable and safe for standard structures. However, with the recent advent of accessible FEA simulation services, designing, testing and guaranteeing the safety of an innovative building project and its materials has become easier, faster, and significantly cheaper.

One of the biggest benefits of FEA simulation services is the accurate determination of material properties. This is where novel research areas like multiscale modelling come into the picture. Using a multiscale model, one is able to use the microstructure (or otherwise each individual component property) to determine the property of the concrete (or otherwise the property of the whole). FEA analysis services requires the FEA consultants to input all the material parameters. The inclusion of all parameters enables precise modelling of all physical stresses on each structural unit. This use of FEA analysis services increases material accuracy in the design of structural components by showing how all stresses may impact on the design of a structure.

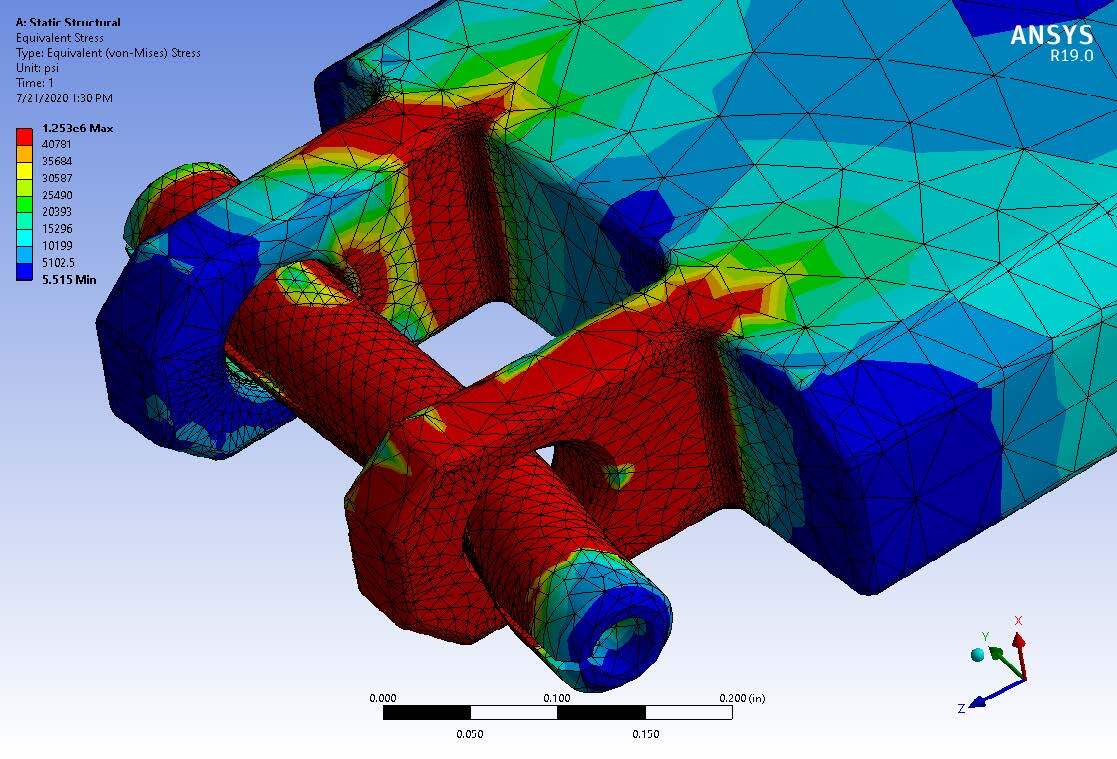

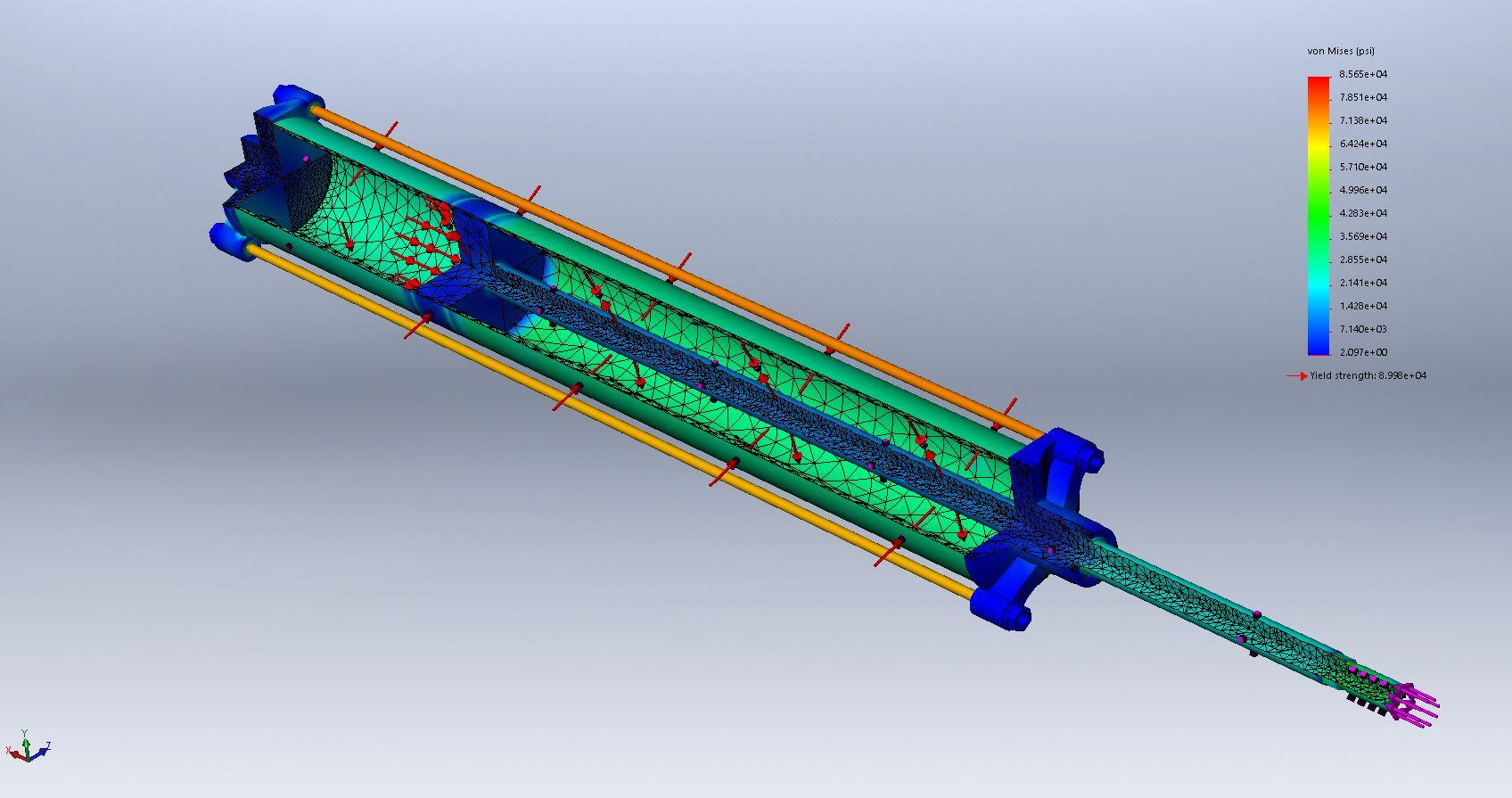

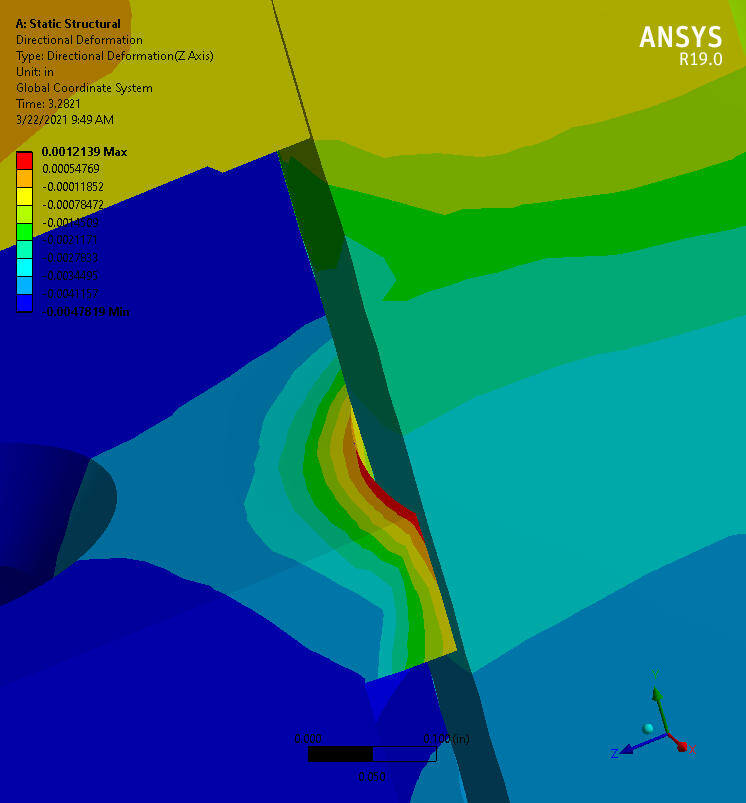

FEA simulation services allows the designer of a structure to model a whole structural system instead of separate structural components. The modelling is helpful in improving the speed of product development. The use of different types of finite element analysis allows the designer of a structure to determine how the stress components in one part of the structure will impact the other materials and components in another separate piece of the structure. This is very helpful not only in determining the reasons for immediate failure, but also failure due to fatigue, erosion, cyclic loads or any stresses which can be modelled in the FEA system.

One of the major structural engineering concerns are earthquakes, and in general, all sorts of natural disasters, both because a large number of buildings are not constructed up to standards, and because the characteristics of such catastrophes are not easily and accurately predictable. FEA simulation services are used to understand the effect of impact loads and stresses on the overall structure of the construction and understand the fracture mechanisms behind the failure of these structures. FEA simulation analysis are very useful in capturing the dynamic behaviour of the loads on structure and understand the nonlinear failure mechanisms of the structure and predict the cycles or impact loads to failure. This allows the FEA consultants to design more robust structures which can sustain these impact loads without initiation of failure.

FEA simulation services assist in reducing many iterations of the initial metal prototyping phase. The prototypes are costly because they take a lot of time and labour to build by hand. Unlike hard prototyping that may take weeks, as a FEA consultant you can use FEA simulation services to simulate the structural system you intend to build. The high-quality simulations in FEA software allow FEA consulting engineers to start virtual testing early in the design process. The ease of using FEA simulation services reduces the designer’s reliance on many physical prototypes and thus cutting prototyping costs. This outcome implies you can cut material wastage and shorten the design cycle.

FEA simulation analysis has a lot of benefits and based on the organization requirements, they can find a right fit which can be a part of the overall design and development process. As newer techniques for mechanical and stress simulations evolve, the FEA simulation analysis are evolving too to the point that these services are the wiling to adjust and tailor their services as per the requirements of the clients.