by mart-admin | Oct 16, 2020

Every business or industry desires a product of immaculate standards. A better quality drives customers, ensures safety, and offers a great life cycle. In the Mechanical, Aerospace, and Civil industries, a component’s standard plays a crucial role in its...

by mart-admin | Sep 23, 2020

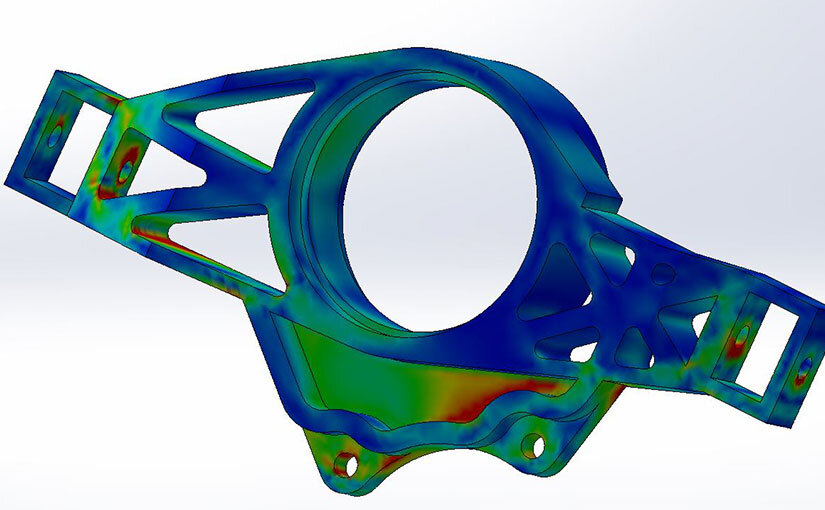

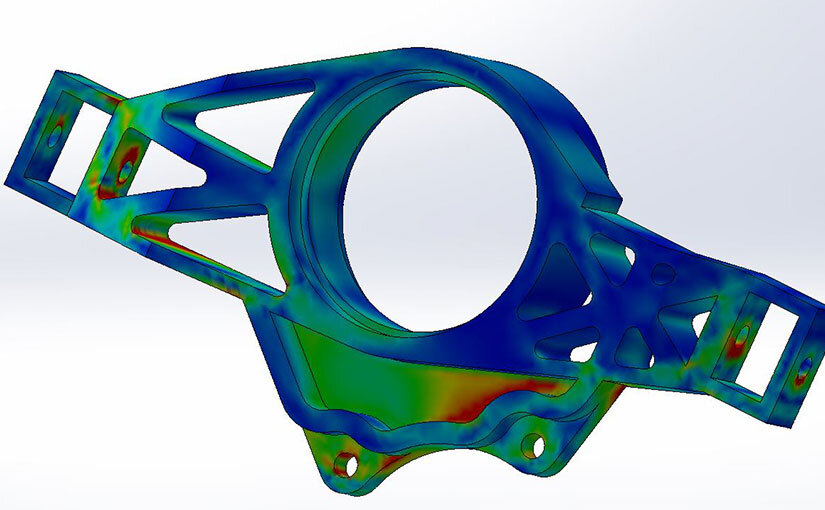

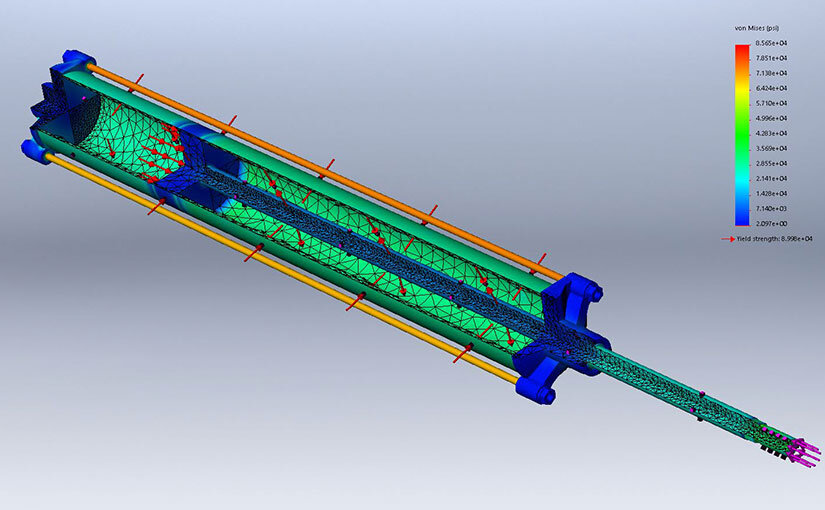

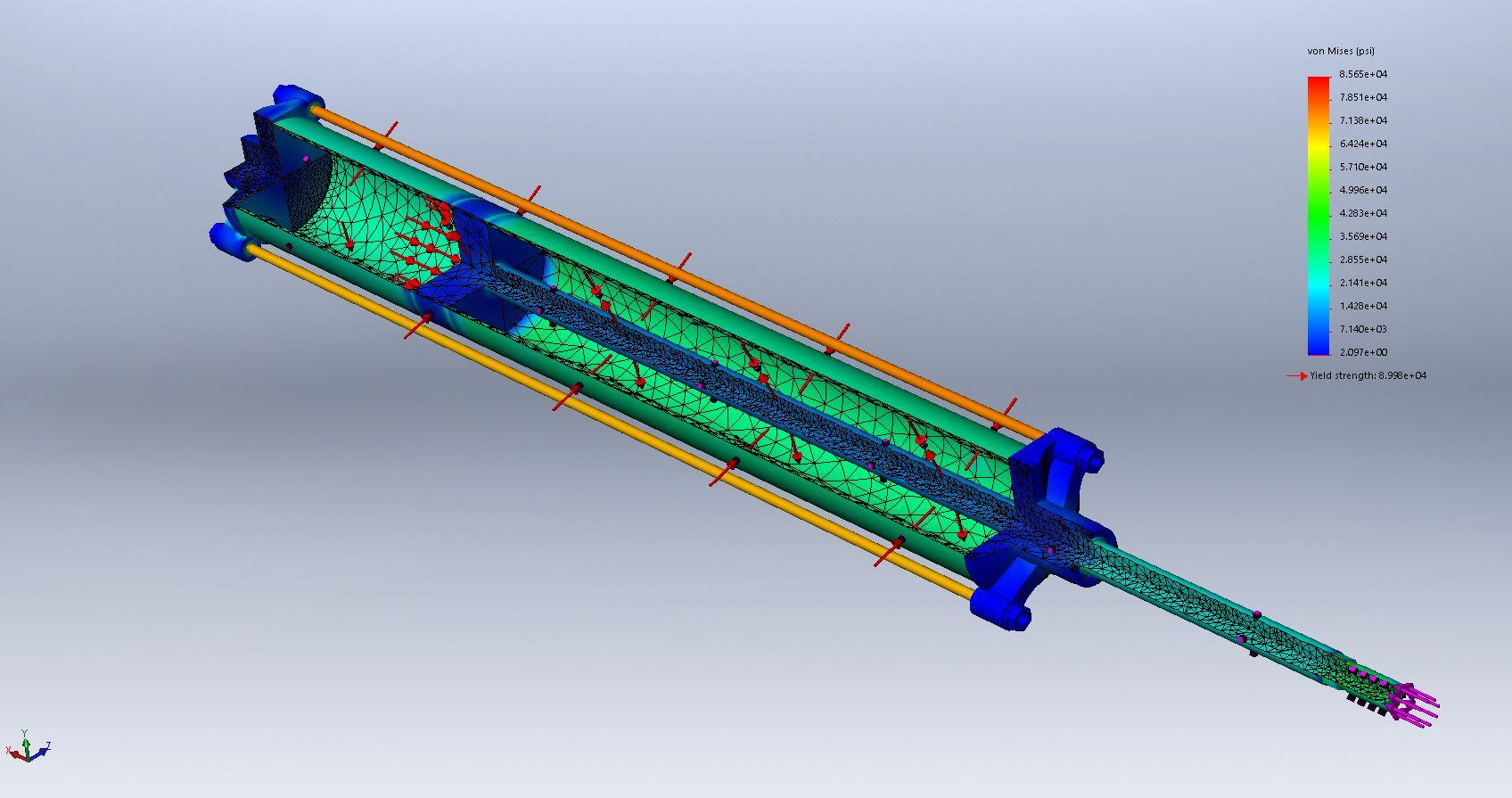

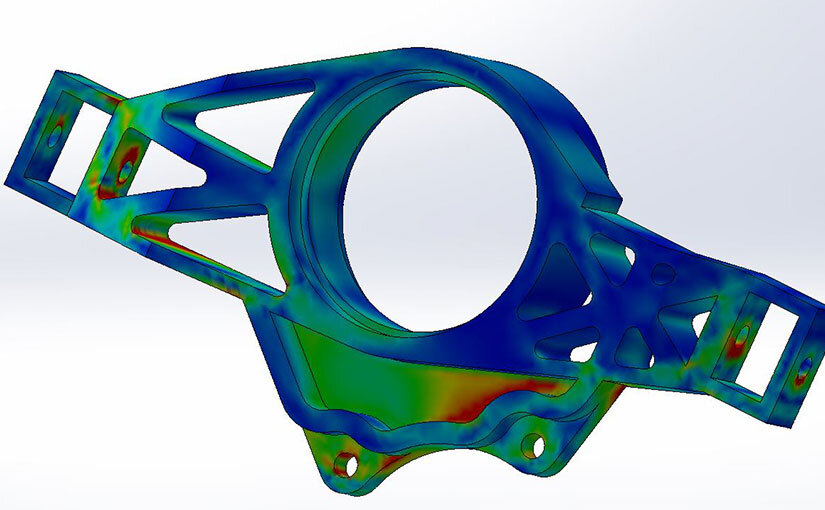

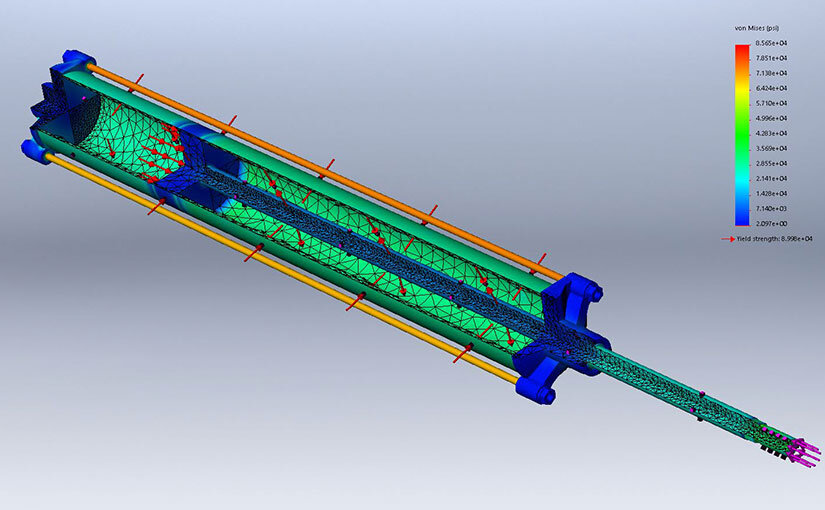

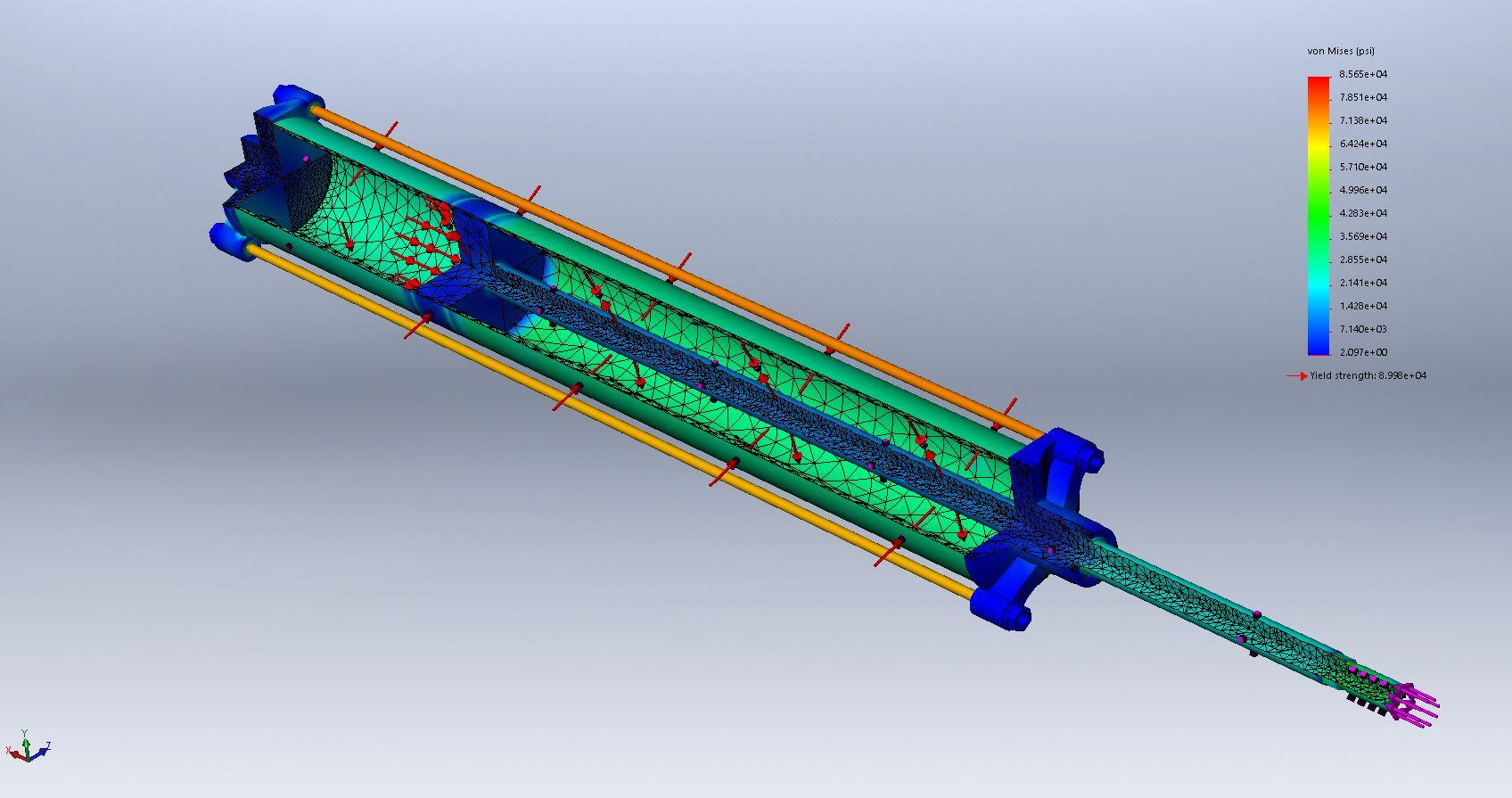

The Integration of FEA The engineering and scientific fields have experienced a tremendous increase in productivity because of the implementation of finite element analysis (FEA) which is a computer numerical analysis program. Having evolved over the years to what it...

by mart-admin | Aug 18, 2020

Finite element analysis (FEA) is a computer process for calculating how a product reacts to forces. Finite element analysis shows whether an aerospace device will break down, wear, and tear out, or perform the way it was conceived. Because of this, information is used...