If you belong to the product manufacturing industry, then chances are you’ve already heard about the concept called rapid prototyping. It is one of the biggest trends in the manufacturing and prototyping industry today.

Rapid prototyping allows you to create multiple scale models of your product idea to further simplify the manufacturing process. Also, rapid prototypes can serve as dummy models to help represent your idea in front of your stakeholders.

But the thing is…

What’s the exact process that goes behind rapid prototyping? And how can you make the most out of rapid prototyping for your business?

If you are curious to find out then we’ve curated all the necessary information for you.

In this blog, you will find out what rapid prototyping is, its benefits, and how can you use it in your business to streamline your product designing process.

Read along.

What is Rapid Prototyping?

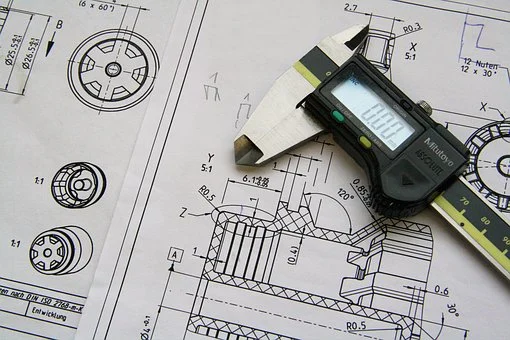

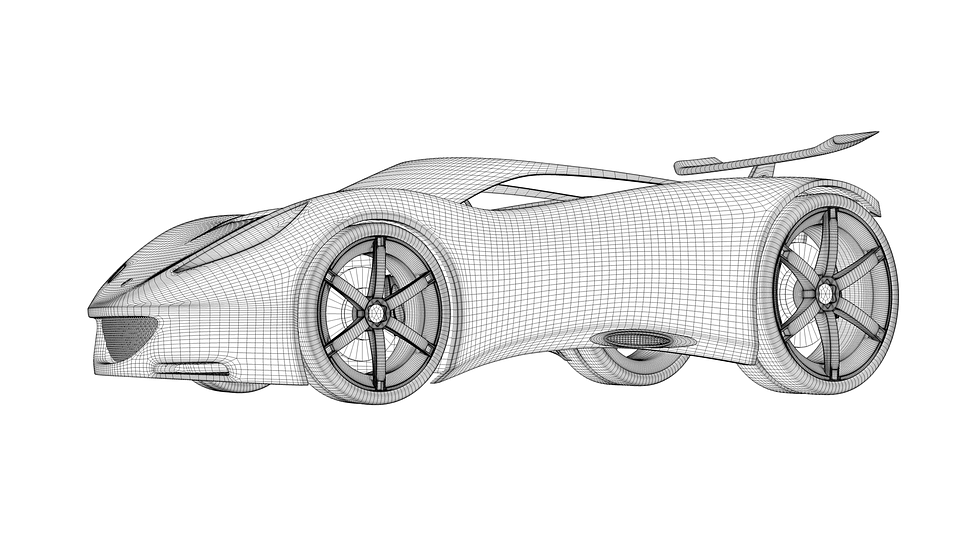

Simply put, rapid prototyping is a set of methods you can use to quickly and continuously create a scale model of your product assembly using computer-aided technology (CAD) data. Nowadays, the term rapid prototyping and 3D printing are used interchangeably as 3D printing is the most important aspect of rapid prototyping.

Rapid prototyping uses an additive manufacturing approach as it is the fastest way to create a near-perfect visual replica multiple times. Subtractive manufacturing, on the other hand, requires frequent rework to remove unnecessary parts which defeat the purpose of rapid prototyping.

3D printing machines follow 3-dimensional design commands from CAD systems and create a product replica by adding layers of liquid plastic, rubber or other synthetic materials. Some 3D printing technologies can also create intricate inner mechanical parts for products with great attention to detail.

Benefits of Rapid Prototyping

Rapid prototyping comes with numerous benefits. Here are some of the most important ones for your business:

1: Thorough testing before production

The most important benefit of rapid prototyping is it allows you to thoroughly test your product early on. You can create multiple prototypes in one go, detect some design flaws in your designs, and create more refined ones in a short amount of time.

Detecting functional and design flaws early in your product can prevent huge costs later on if flaws are identified during final production. Nowadays with 3D printing, you can also replicate inner mechanical parts of your product with finer details. This helps you to work on both your product’s aesthetics and functionality.

2: Cheaper and easy to operate

3D printing has been there since the 1980s. However, due to its huge cost and heavy machinery, it was only affordable for big companies back then.

But that’s not the case today. Due to the rapid advancement in technology, 3D printers have become much affordable and sport a compact design. Buying a 3D printer has become so convenient that many tech enthusiasts own one in their home.

For a business, 3D printers come with a variety of functions to suit different requirements of products such as aesthetics, complexity, and mechanics. You can select the 3D printer most suitable for your business and get started with rapid prototyping straight away.

Also, unlike CNC machines which require special expertise to operate it, 3D printing can be done by following simple instructions. If you have a decent knowledge of CAD and product designing, operating 3D printers is quite easy.

3: Faster realization of your product concept

Rapid prototyping tools simplify the process of generating new product ideas by allowing frequent creation of visual replicas. Having a solid 3-dimensional replica in front of you helps you explore new ideas and rework on them with ease.

You can work on your product step-by-step by creating the initial prototype and add the changes until you are satisfied with the end results.

You can also share the progression of your product design with your colleagues, project partners, and potential investors which is much better than sharing an imaginative concept. Rapid prototyping lets you explore new possibilities to improve your product before transferring it into the production line.

4: Speeds up the Manufacturing Process

Although prototyping is an important process in product design, it is considered as a bottleneck. It takes a lot of time and effort to come up with a brand new product idea and turn it into reality. The most tedious part of product designing is working on the visuals and intricate details of your product.

This is where rapid prototyping shines. It significantly reduces the time taken during prototyping and redesigning phase of product design. Also, tweaking your product to perfection early on speed up the final manufacturing process.

How to make the most of Rapid Prototyping?

By now, you must’ve understood the importance of rapid prototyping for your business. But if you follow these 3 golden rules, you will get the maximum benefit from it.

Interested? Let’s start with the first one:

1: Understand your product needs

First of all, it is important to understand your prototyping needs before selecting the right rapid prototyping approach.

You can select your rapid prototyping tools according to the following factors.

- Product shape and dimension

- Attention to detail

- Surface finish

- Rework time required for the prototype

- Production approach

2: Choose the Right 3D Printer

As I’ve mentioned before, 3D printers come in all shapes, sizes, and functionality. There are 3 major 3D printing machines that are used commonly today. Let’s have look at them:

- Fused Deposition Modeling (FDM): FDM creates 3D models by melting and extruding thermoplastic filament. The quality of the final product is very basic with a poor surface finish. It is ideal for hobbyists with basic prototyping needs.

- Stereolithography (SLA): SLA is the first-ever 3D printing machine that was introduced way back in 1980. It uses a laser to cure liquid raisins into hardened plastic. SLA provides numerous material choices in 3D printing, making it the most popular 3D printing machine for industries worldwide. Prototypes from SLA have a fine attention to detail and a cleaner surface finish.

- Selective Laser Slinting (SLS): Best for additive manufacturing, SLS 3D printers use a high-powered laser to fuse small particles of polymer powder. SLS outputs prototypes with extreme attention to detail and moving mechanical parts. The most common material used in SLS is Nylon.

According to your product needs, you can select the most suitable rapid prototyping machines for your business.

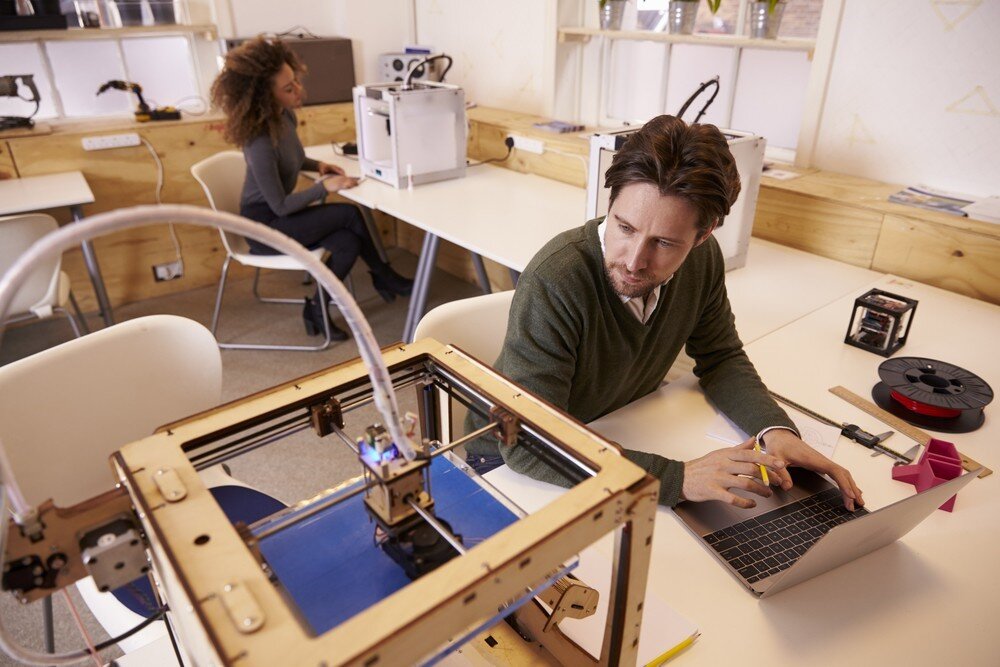

3: Have a dedicated prototyping staff

Most importantly, prototyping should be done by an experienced and creative staff that know their way around. After all, product designing itself is a creative process and needs a creative mindset for successful results.

Also, having a dedicated prototyping team streamlines the production process by conducting all the prototyping activity efficiently and reducing the turn-around time.

To go a step further, if your budget allows it, we would highly recommend outsourcing the rapid prototyping services to a competent product design company in your local area. Not only they provide valuable expertise in prototyping but they also help you focus on other important business activities.

Final Thoughts

In conclusion, rapid prototyping has changed the product design industry forever. Using the latest technology and expertise, you can create multiple replicas of new product design to get the perfect final product and streamline your product designing process.

All the factors mentioned above will help you make an educated decision for selecting the perfect rapid prototyping strategy for your business.

Speaking of which, if your business is in Houston, Texas and looking for rapid prototyping, Industrial design, and custom design solution services in your area, we will be more than happy to help you.

Just take a look at our comprehensive portfolio of 3D printing services. If your products need the same treatment, send us your queries and we’ll do our best to help you out.