Among all the industries that use rapid prototyping regularly, the medical industry affects us on a personal level. Also, it is one of the fastest-growing industries with rapid inventions and technological advancements.

With the medical instrument prototyping and other rapid prototyping methods, the healthcare industry is getting better with every passing year. Experts in medical industries can bring innovations in medicines, medical product design, prosthetics, surgeries, and other fields in healthcare, thanks to rapid prototyping.

With that being said, the future of medical products and instrument design is filled with new possibilities for technological advancements.

In this blog, we will take a look at the bright future of rapid prototyping in the medical industry. We will cover the major areas in medical industry where prototyping plays a key role.

Medical Devices

Whether it’s a simple product like a scalpel or complex one like a heart rate monitor, rapid prototyping allows the medical industry to bring innovations in these products.

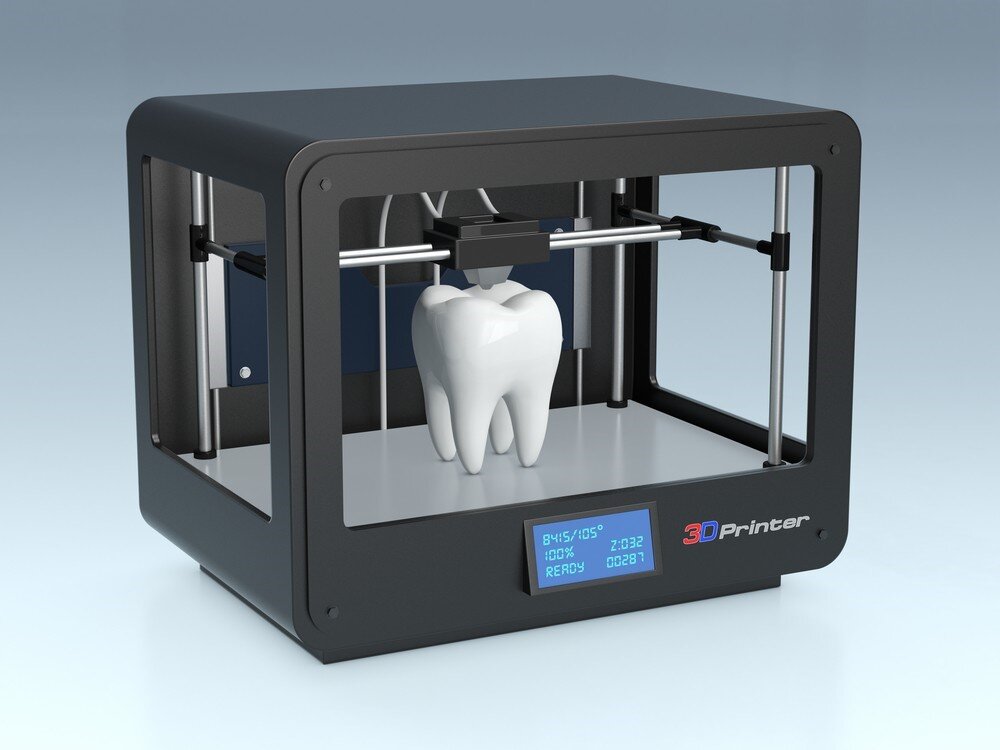

Medical development services use 3D printed prototypes of medical equipment to find out the possibilities of improving them. Through rapid prototyping, we can change the design, movement, and add new functions to improve its efficiency.

Another crucial aspect of medical instruments designing is accuracy. Unlike other industries where minor errors in the product can cause production to halt at worse, having even a minute error in some of the medical products can directly cause harm to a person.

Prototyping helps to update the products without compromising the precision. With virtual simulation, you can predict the minor errors in medical devices early on and rectify them before using them on a real person.

The future of medical instruments prototyping will include an interactive designing mechanism. With the rise of augmented reality, experts can virtually interact with the equipment to see how it performs in a real-life scenario. We can experience the product’s size, shape, and dimension in a real-world environment and make changes simultaneously.

Also, inventions in medical instrument designs will be even faster thanks to 3D printing.

Medicines

Prototyping is currently used to determine the size, shape, and dosage form of pills where it cannot be done with any other method. Also, it’s used to predict the potency of the medicine and its effect on a human body before mass manufacturing.

The future of medicine prototyping technology focuses on maximizing the automation, streamlining the workflow, managing huge data to create more efficient medicines. The sheer amount of information available for pharmaceutical sectors requires rapid prototyping for A/B testing and measuring the feasibility of the medicine.

When it comes to new medicine formulation, Rapid prototyping helps to determine the dosage, managing the chemical compositions, and bulk manufacturing methods. Also, it can help in managing the selective function of medicine.

Overall, medical development services will provide medicines with maximum results and location-centric effects.

Surgeries

The additive prototyping approach is perfect for creating 3D replicas of human organs to find the exact complexions and the right surgical approach. The results from x-rays, CT scans, and MRIs can be converted into a 3D replica with rapid prototyping.

Rapid prototyping is mostly used by dentists and orthopedics to create a replica of bone damage, dislocations, and repairing progress. It can also be used to understand the deformities in teeth, re-positioning, or unnatural growth. All these factors help the surgeon to point out the exact issue and work on it in the best possible way.

The future of prototyping in surgery will include more interactive surgery simulation for delicate human organs like brain, heart, kidneys, etc. Also, prototyping will help patients to understand the surgical procedure and take better care of themselves post-surgery.

Implants and prosthetics

Before Rapid prototyping, Prosthetics were designed using the standard measurements of damaged organs. However, it took a significant amount of time designing the final prosthetic. Also, any small error in prosthetic leads to redesigning from scratch. It was a time-consuming process with uncertainties.

Since the introduction of the medical prototyping services, designing prosthetics has become much faster with little to no errors. Doctors can take the perfect measurement of the damaged part of the body and 3D printers process it to create the prosthetics with the exact size and dimensions.

Prosthetic doesn’t fit well? Don’t worry, rapid prototyping can create multiple replicas to make necessary changes. Once they found the perfect size and dimensions, doctors can then create the final prosthetic that fits the size, dimensions, and color that looks like the exact body organ.

This approach is also used in creating implants in the safest possible way. Whether it’s cosmetic or surgical implantation, rapid prototyping has made it much cheaper, easier, and safe.

Today, we can create prosthetics and implants that fit in a person’s body like an old glove. We can create a replica of a lost body part that is hard to differentiate. In the future, we might be able to create prosthetics and implants that mimic the functions of the natural body part.

Robotics

The concept of a half-human half-machine is quite common in a fictional world. However, the future of medical prototyping development might bring it into reality.

With the fusion of nature and science, experts are now creating bionic arms that can mimic the natural movement of hands and legs. Our current technology allows us to create robotic arms and legs that can perform functions like running, grabbing stuff, picking things up, etc.

However, there is a significant lag in processing commands and executing them. With bionic arms with neural networks, we can create an arm that can type complex sentences, lift heavier things, and even play sports like volleyball, baseball, etc.

Scientists are also planning to bring the medical instrument prototyping to a point that we could print stem cells, skin cells, RBCs, WBC, and even complex neural systems at moment’s notice. Although it will take a considerable amount of time to mimic nature, we have taken steps in the right direction.

Final Thoughts

Medical and healthcare industry has come a long way since its inception. From natural ingredients to cure severe illness to 3D printing the lost nose, we have seen tremendous development in medicines that have extended our life expectancy and enhanced our lifestyle.

Rapid prototyping has played a key role in speeding up technological advancements in the medical industry. It allowed numerous experimentation, realistic representation, and virtual simulations that lead to rapid experimentation.

The gap between idea generation and its commercialization has been narrowed down to a few months thanks to rapid prototyping and medical prototyping services.

Speaking of which, If you’re looking for specialized medical prototyping services in Houston, Texas, we are looking forward to helping you with our prototyping expertise.

We provide highly customizable prototyping services like medical product design, medical instrument design, medical development, and instrument prototyping services. We specialize in medical instruments, machinery, and invention help.

Take a look at our work to see exactly what can we do for you.