For marketing to be successful, there has to be a stellar product on offer. The product needs to have gone through a creative design process that filters through vague concepts and arrives at a few. These are usually capable of creating impact and the great ones go on to make it to production and marketing.

World-class companies, therefore, approach product design in innovative ways as they always design for success. They will not only engage the best ‘inhouse brains’ at their disposal but also, enlist experts from engineering design firms.

The techniques that are consensually arrived at, are usually brilliant enough to guide the product development process on, to success. A mechanical design firm uses various step-by-step analytical tools that rely on many in-depth case studies.

Value Stream Mapping is also at the forefront of their techniques as its influence on product development can not be ignored. This methodology is why their self-directed product design teams are so successful.

Firms, therefore, rely on mechanical engineering services due to well, the very reliability that these firms have witnessed. Product development services are highly sought after because they have produced consistent results that manifest with successful products, time and again.

If you are an entrepreneur wondering whether engineering design firms are worth the buck, you should consider their results. These results are arrived at in several ways that include, but are not limited to:

1. Planning a product based on the goals of the organization as dictated by the market

Smoothly flowing through the early stages of a product’s life cycle is a key element that relies on good plans. Well-defined products from early on tend to do better than products that were not given sufficient planning. Early design work will put you ahead of competitors more often than not since you have eliminated product launch uncertainties.

2. Overcoming customer resistance especially for products that have advanced technological content

By focusing on how a given product will be of use, products are made more appealing to customers. Sales teams can therefore pitch the product with its problem-solving capability at the forefront. This means it eventually resonates with customers once a target group and a plan-call for it is identified. Such a customer-oriented approach rarely disappoints as customers are always looking out for solutions that ease their afflictions.

3. Addressing the five fundamental questions that pertain to products

When time, effort, and money are invested into a product, there’s a need for thorough examination and review. The said product can greatly affect the credibility, reputation, and finance of a company so keen attention is apportioned. Engineering design firms address the issue by answering the fundamental questions that surround a product’s design. These (Why, What, How, Who, and When)? questions that pertain to each product, when answered appropriately result in stellar products.

4. Leveraging available tools and techniques as a means to a successful end

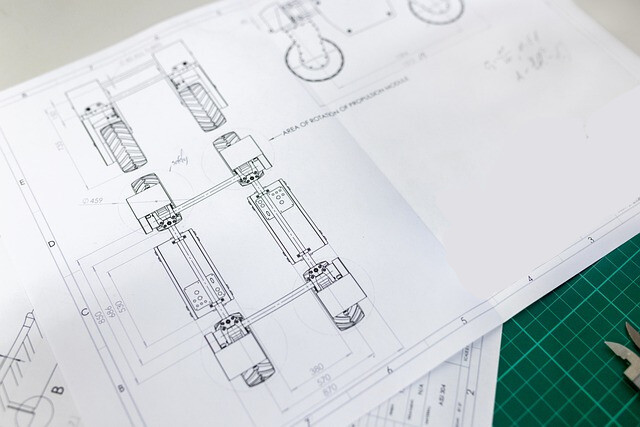

Developing a product that is fit for function, manufacturing, reliability, and servicing is ideal design-wise but difficult to achieve. The creative design process is therefore broken down into smaller steps for easier management. The focus is always on eliminating issues of the design for the sake of disassembly, reliability, and maintainability. This is because different tools easily have an impact on the new product development process. The sub-phases include the Concept Development phase, Design, and Development, Analysis and Testing, and the Process of Product Creation.

5. Focusing on various external and internal factors when approaching product design

Technological advances have sped up the rate of innovation while failing to take into account the impact on the environment. This trend has seen a steady rise in the likelihood and occurrence of environmental crises. Neglecting the safety factor means there’s a need to borrow from the future. Products are being studied, now more than ever, in a bid to determine their environmental impact before sending them to the market. This is a critical aspect that is now present as product life cycles become ever shorter.

This focus covers modularity for the sake of product maintenance once it hits the market. How the product will be repaired and parts replaced is important as the recyclability of a product is important. With a focus on materials, management, modern manufacturing, and customer considerations, the process is bound to be more successful. This is, besides, the focus on product design teams, information, cycle time, the development process, and suppliers.

The areas that are crucial to successful product development therefore include:

- A self-directed product team and its advantageous characteristics.

- Evolving product creation strategies and processes

- Innovative design techniques

- Advanced principles of design for manufacturing

- Modern design for disassembly, optimization, and ergonomics.

Conclusion

The above techniques are consistently being used by world-class companies to guide the development of market-ready products. This is achieved by leveraging analytical tools with various case studies that leave little room for error. With the recent development in lean technology and information technology, value stream mapping is more emphasized as its influence on product development is undeniable.