FEA or Finite Element Analysis is a computer-based simulation technique that empowers experts to solve real-world problems. This advanced computation tool produces detailed results accurately, quickly, and cheaply, which is often impossible with experimental investigations. Skilled FEA companies offering FEA simulation services can eliminate the need for manual testing and can deduce accurate output using FEA simulation.

Adding on, advanced computational tools such as FEA is the explanation. To the obvious question, of how continual advancements are possible in the industries nowadays? Being a versatile tool, many prominent companies offer FEA services to help businesses, individuals, and entrepreneurs with the best possible solution. The plethora of benefits associated with FEA makes it a favorable tool. For developing sealing and other solutions in complex applications for the Oil and Gas sector.

FEA in Oil & Gas Industry

The long-term reliability of components involved in the oil & gas sector is vital. Contrastingly, a few decades ago, engineers and experts were dependent on hand calculation and experimental investigations to design complex components and parts. Often this process was time-consuming and involved errors leading to other severe problems in assembly or functionality.

Fast forward to today, the oil & gas industry is blessed with a prolific tool, namely the FEA. Although a few people might think FEA to be a child’s play. Contrary to this belief, FEA is quite a convoluted and technical tool that requires years of expertise and acumen. For this reason, seeking FEA consulting services would be advisable to finalize designs much quicker and precisely without making a hole in the pocket.

Benefits of FEA in Oil & Gas Industry

Components and parts used in the oil & gas industry need to withstand harsh operating environments, chemical aggression, and extreme pressure and temperature. FEA simulation allows designers to accurately predict the effect of all these factors on the components. This, in turn, helps them to develop parts taking all these factors in their mind.

Not only that, there are many other benefits of FEA in the Oil & Gas Industry-

1) It helps ensure proper standards

Every second is precious for the companies and people working in the oil & gas sector. Owing to the high cost involved, components designed for this sector need to be of the highest standard and quality. Often this is only possible with FEA that allows experts to simulate parts in actual working conditions to make any necessary alteration beforehand.

2) It eliminates the need for real-life analysis

FEA removes the need for testing components and parts in the real world. Moreover, it helps designers assess the detailed simulation to produce the desired component without stretching the budget and the time frame. Thus, saving time, material, and resources. To extract the full potential of FEA, consulting FEA companies offering oil field tools design services and drilling tools design services would be beneficial.

3) Accurately determines the output

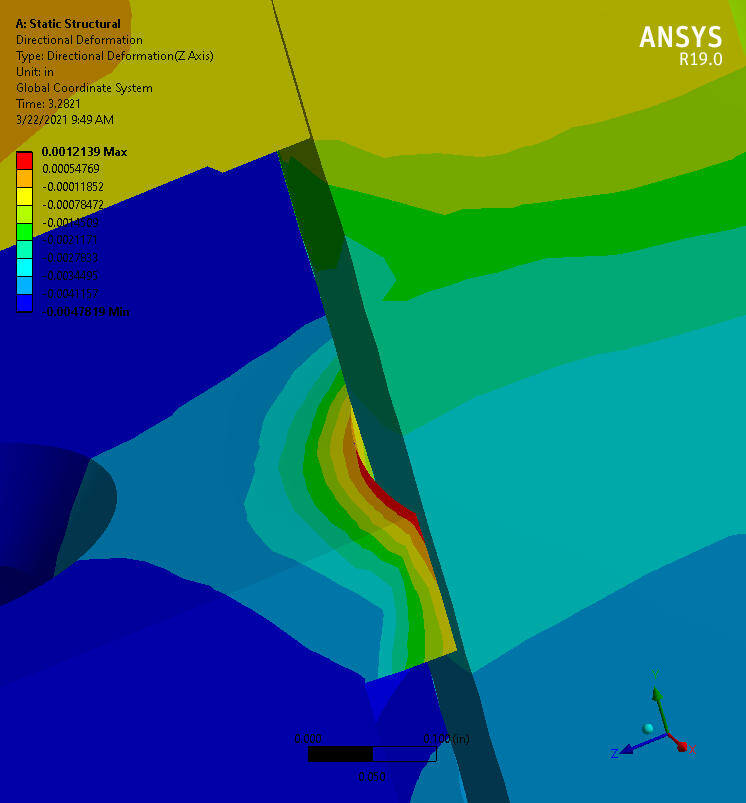

FEA empowers experts to precisely deduce the outcome by showing results in detailed graphs and intricate simulations. Thus, without the need for strenuous hand calculations, experts and FEA companies can determine the design’s scope and limitations. Moreover, with FEA analysis, weaker areas can be identified quickly to incorporate any required modifications. Furthermore, with FEA, designing oil & gas industrial components has become a much more accessible, reliant, and quicker process.

4) Minimizes the need for modifications

FEA in the oil & gas industry helps designers and engineers develop the desired component with just a few iterations. This is how FEA helps in saving money and resources. Moreover, eliminating the need for actual testing many experts offering FEA consulting services would expedite the process.

5) Minimizes the chances of component failure

Component failure in the oil & gas industry would be highly undesirable. This involves not only potential life threats but also involves huge costs and time loss. Thus, the reliability of any component is the utmost priority of experts working in the oil & gas industry. Using the FEA tool, these experts can minimize the chances of component failures by accurately developing parts taking the factor of safety in mind. Moreover, using FEA simulation, weak areas of any component can be precisely judged without the need for real-world testing.

6) Provides deep insight

FEA allows not only the design team but also other members of the company to gain insight into the physical aspects of the component. Additionally, it’s easier to comprehend the working of the part in the actual scenario with FEA. This, at last, helps all the teams to get into unanimity.

Conclusion

To be honest, the advantages of FEA in the oil & gas universe are innumerable. This is because, being an intricate tool, FEA helps experts save money, time, and other valuable resources. Judiciously employing FEA in developing various complicated parts and assemblies would be profitable for sure. However, only an expert can harness the full potential of the intricate FEA tool. Thus, consider seeking assistance from reputable FEA companies to maximize the return on your investment.