Flow is a basic property of any fluid, and fluid flow plays a key role especially in the oil and gas industry. It is equally important to understand the fluid flow characteristics whether it is transported from one place to another in a pipeline or whether it is stored in a container or a tank for a long time. It is important to consider properties such as the speed and the viscosity of the fluid flow as they play an important role in designing the overall infrastructure of the industry. The amount of fluid, flow pressure and the potential difference also needs to be managed which is one of the main reasons why flow engineering services are important especially in the oil and gas industry.

Flow engineering consists of first understanding the kind of fluid under consideration, which can be either any form of oil or gas, second understanding the purpose of the engineering. Whether it is transportation within an acceptable pressure and temperature limit in a stipulated time with minimum losses or whether it is storage in a tank for a long time considering the safety and storage aspect of the fluid. Flow engineering also considers the impact of the surface roughness of the walls on the fluid flow within a pipe or a reservoir. The amount of drag experienced by the fluid flow affects the overall speed of the flow within the pipe. Ideally at any point within the pipe, the flow should be quasi-steady, thus minimizing any losses or any increase in temperature and pressure within the pipe. Therefore, it is necessary to minimize the surface roughness as well as the effect of friction of flow so as to avoid the fluid to become heavier while being transported or stored, especially in the oil and gas industry. The final consideration in flow engineering is the presence of elbows, reduces, flanges and bends in the pipelines carrying the fluid from one place to another. These produce a lot of force and direction changes within the fluid flow leading to the formation of eddies and additional pressure losses in the pipes. If they are not designed properly, it can also lead to choking of the flow within the pipe making it difficult for transportation.

Considering the previous reasons for the importance of flow engineering in oil and gas, flow engineering is used to optimally design the pipes such as deciding on the pipe diameters, surface roughness and length of the pipes required for carrying the fluid. The fluid flow in a pipe happens due to the fluid moving from a high-pressure region to a low-pressure region or due to the potential difference generated within the pipe. Flow engineering helps us to design this potential and pressure difference, so that the flow can be transported safely without causing any damage or risk to the pipeline. Another reason for the importance of flow engineering is designing of pipes and external equipment considering the external environmental considerations. For example: Considering transport of oil and gas through underwater or oceanic pipelines. These pipes have to withstand not only the internal pressure from the fluid flow, but also the external pressure from the water or waves through which they are being subjected. Flow engineering allows us to consider these environments and pressures to design pipes which can withstand the pressures as well as maintain the fluid flow velocity and internal pressure for the fluid to move from one place to another in a timely manner.

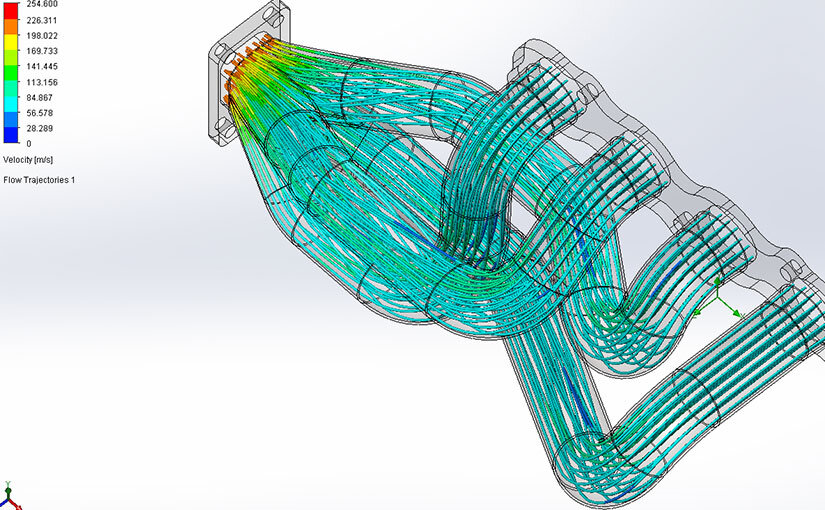

For carrying out Flow engineering, various CFD consulting services and CFD engineering services are present which carry out the same. The equation of motions used by CFD simulates the fluid flow through pipes thereby providing information such as speed of the flow, temperature changes within the flow and internal pressure exerted by the fluid flow onto the pipes. This is very useful especially while designing elbows and bends because CFD simulations calculate and enable us to visualize the fluid flow through these geometries. Thereby, making us aware about any losses or recirculation occurring within the pipe to minimize any pressure losses or delays. Based on the CFD results obtained, the CFD consultings provide consultation in terms of change in design of the overall piping system or speed of the flow to enable its motion.

The flow engineering services design the piping configuration of the system through pressure differences so as to transport the fluid over larger distances and minimizing any corrosion or long-term effects on the transport infrastructure of the fluids. The flow engineering services also enable design of complex paths through which the fluid flow can occur to the location. The flow simulations services help us to analyze effects such as sloshing of fluids such as oil in a container or tank especially when they are stored and transported over long distances. The flow simulation services also analyze the effect of the pressure on the pipes and to make sure that the pipes are able to withstand the pressures without bursting or deformations.

The oil and gas industry has products which are fluid in nature both in its raw and finished form. Based on the various reasons and considerations in the oil and gas industry, it is important that we consider flow engineering to improve productivity in the industry as well as maximize the use and efficiency of the fluid resources, which are a key to the survival of the industry. Flow engineering needs to be developed more so as to maximize the potential of these fluids as well as find faster ways to transport them across locations safely.