Design Optimization Services

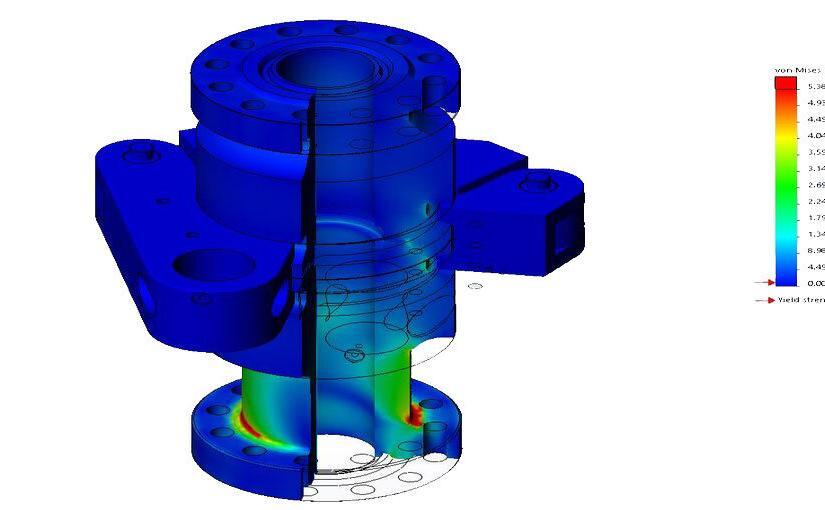

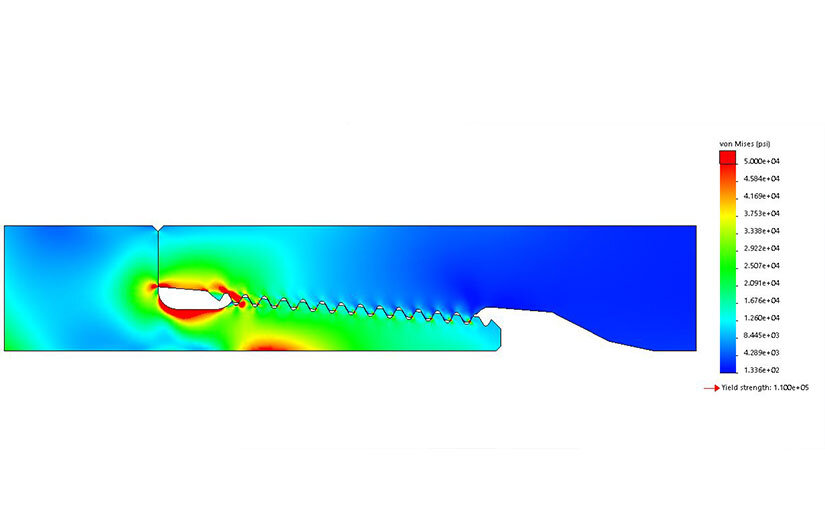

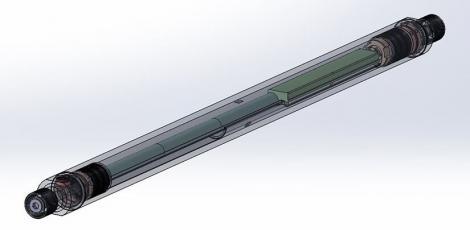

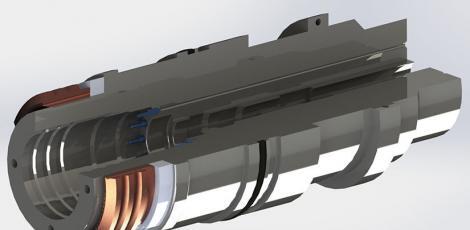

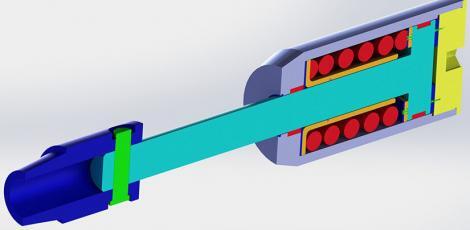

Design optimization begins with understanding the objective and required specifications of the component, or product. Once specifications are defined, Imaginationeering will explore optimizing the performance and the design of your part or product by changing one parameter at a time and run FEA simulation or CFD simulation after each variable change takes place.

Finite Element Analysis is the perfect tool to optimize any component or design, if used properly, in order to avoid any failure and to make sure that your parts are being manufactured effectively. Aerospace Industries heavily use FEA simulations to keep the weight of their parts at its minimum while meeting the strength’s requirement.

Design optimization of a product or a component will make sure that the strength of your component is meeting its required safety factor while keeping the weight as light as possible.